Kent Vander Velden

Freelance Analytic Creator

I create analytical solutions for product prototypes and scientific research. This portfolio is a selection of my work and experiments.

info@confluencerd.com

Other projects

- Plant phenotyping instruments

- Deep learning computer vision of plants

- Telepresence pharmaceutical dispensing

- Reverse engineering precision agriculture monitors

- Remote telemetry add-on for precision agriculture monitors

- Localization for autonomous agriculture

- Handheld spectroscopy

- Analytical software tools

- Design proposals

Finding next-gen fertilizers

Finding next-gen fertilizers

Fighting nitrogen pollution

Fighting nitrogen pollution

Product exhibits

Product exhibits

Kent on YouTube

Kent on YouTube Spectroscopy

Spectroscopy

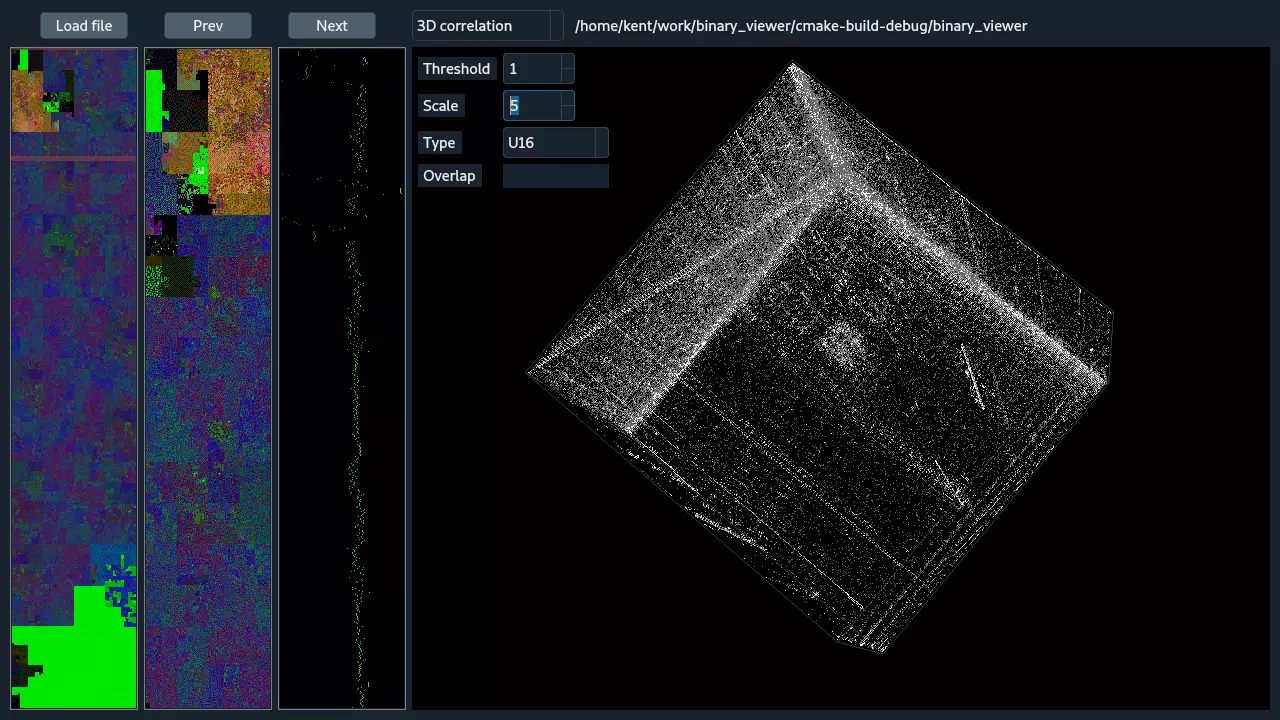

Binary reversing

Binary reversing

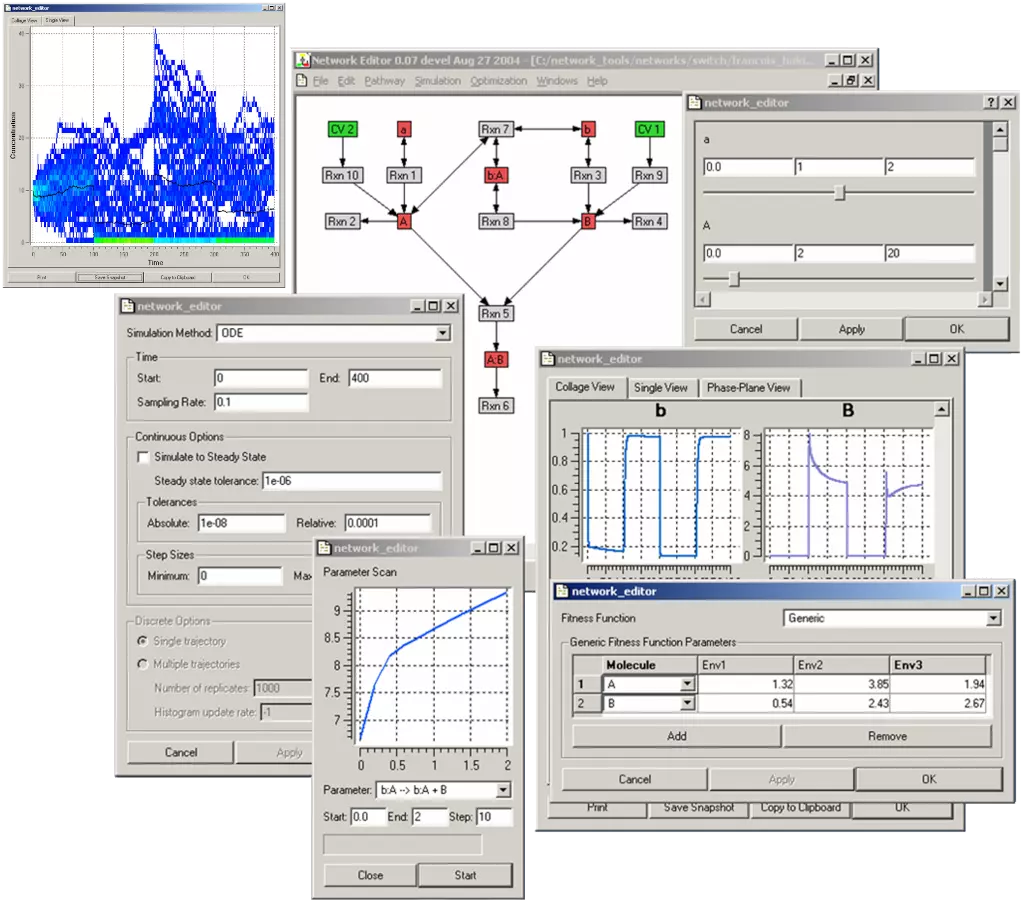

Synthetic biology

Synthetic biology

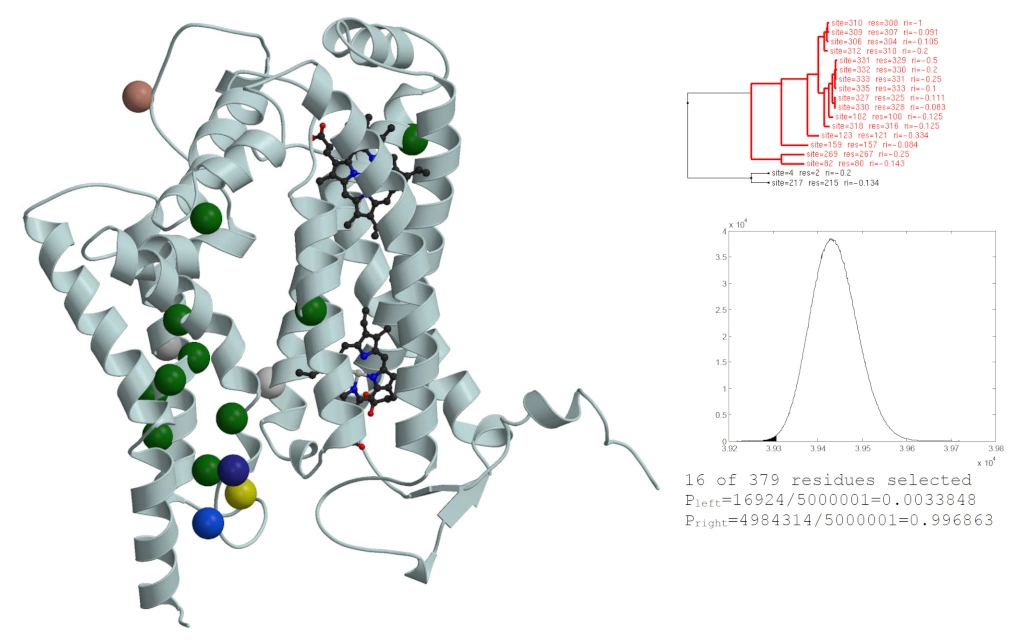

Protein function-structure divergence

Protein function-structure divergence

Split-tester

Split-tester

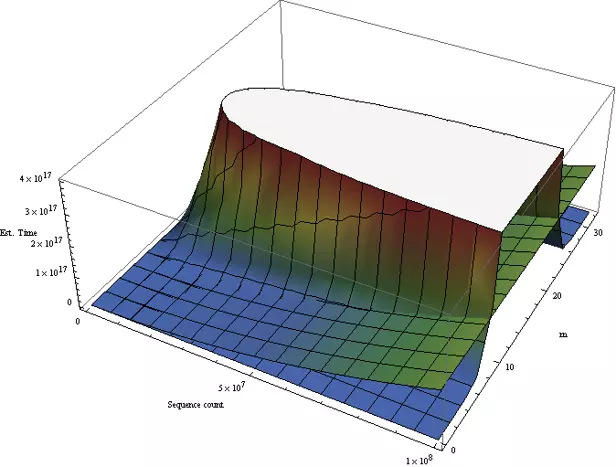

Protein evolution

Protein evolution

Lectures

Lectures

Machining Applications

Machining Applications

Vander Velden Law Firm

Vander Velden Law Firm