A

quick change tool post may be a luxury for a hobbyist, but one that will

be appreciated over and over. On smaller lathes, adding one may require

some modifications.

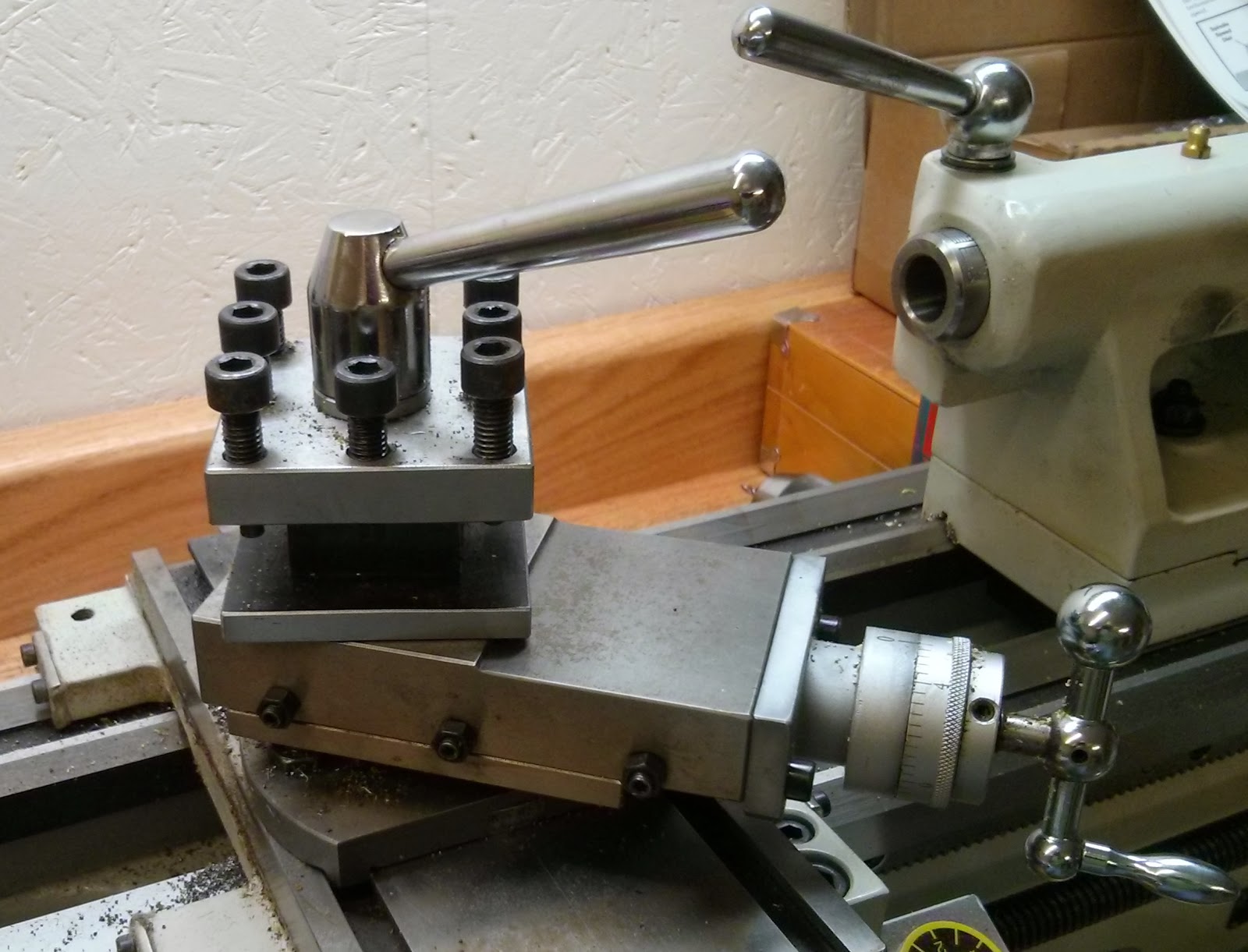

The South Bend 8k SB1001 8"x18" lathe comes with a four-way turret tool

post. These facilitate changing between multiple tools, but require

shimming tools up to center. Quick change tool posts use adjustable

height tool holders, eliminating shimming.

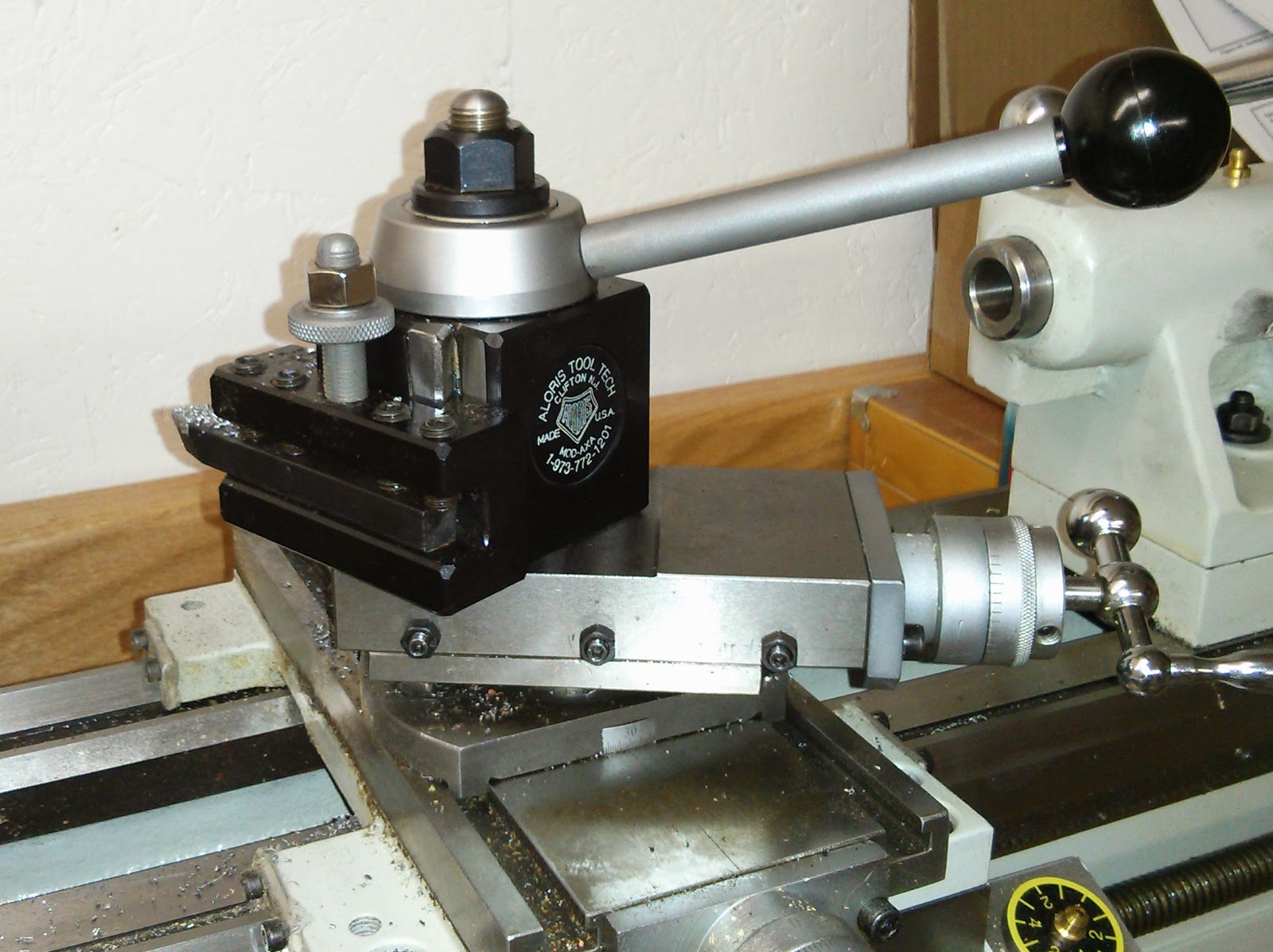

The Aloris tool post is the

original standard, made in the USA, but there are imports available that

are less expensive. The Aloris AXA comes with a 9/16-18 shaft and a

threaded metal plate that could be machined to fit a compound t-slot.

Unfortunately, the SB1001 does not have a t-slot in the compound so the

compound slide must be modified.

A couple screws, either side of the compound handle, hold the compound

slide in place. Remove them and push the compound slide off. Be aware

the jib that may also slide off.

Tap out the original tool post shaft. It's held in place with knurling

on the post and a pin between it at the compound. Remove the jib set

screws.

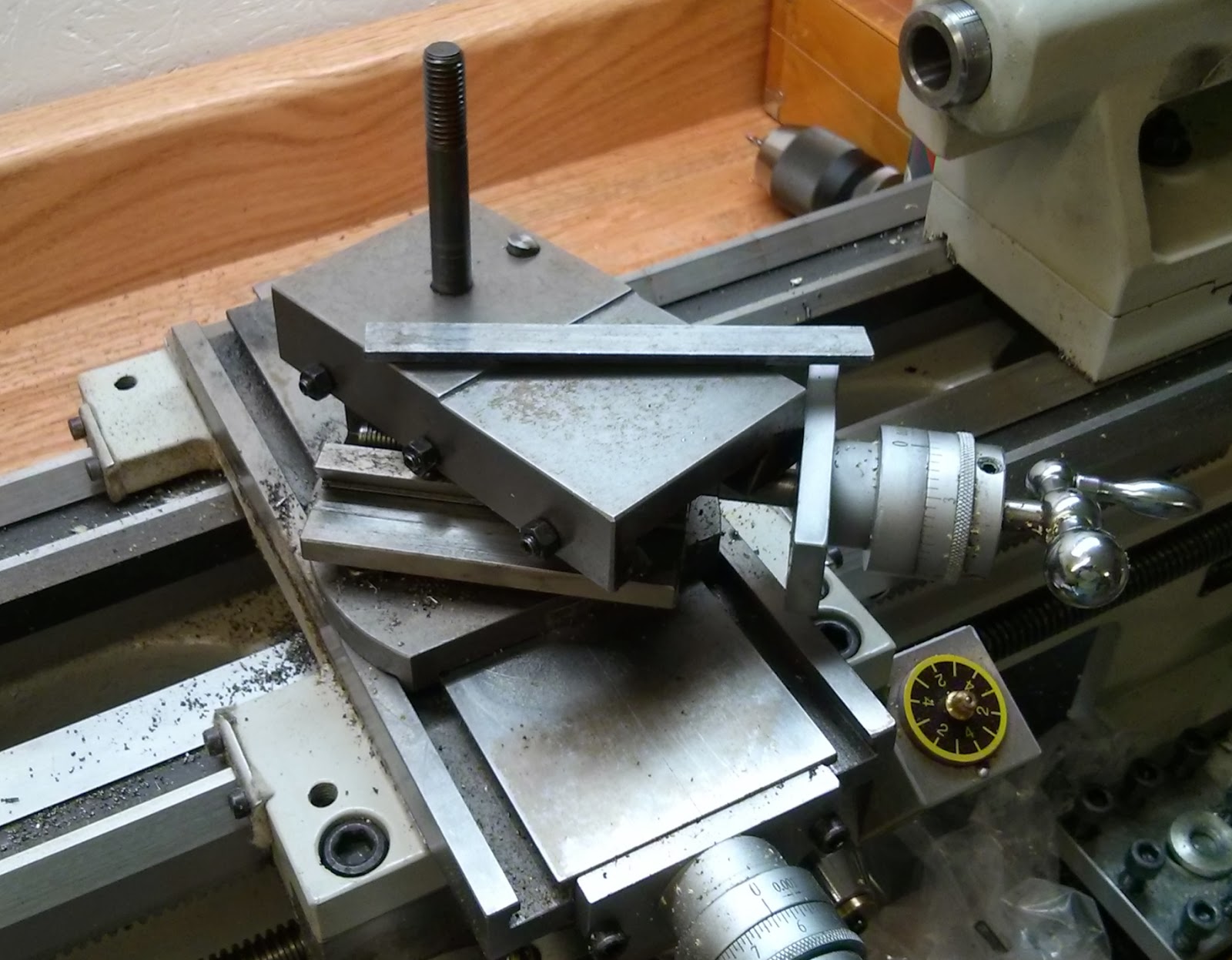

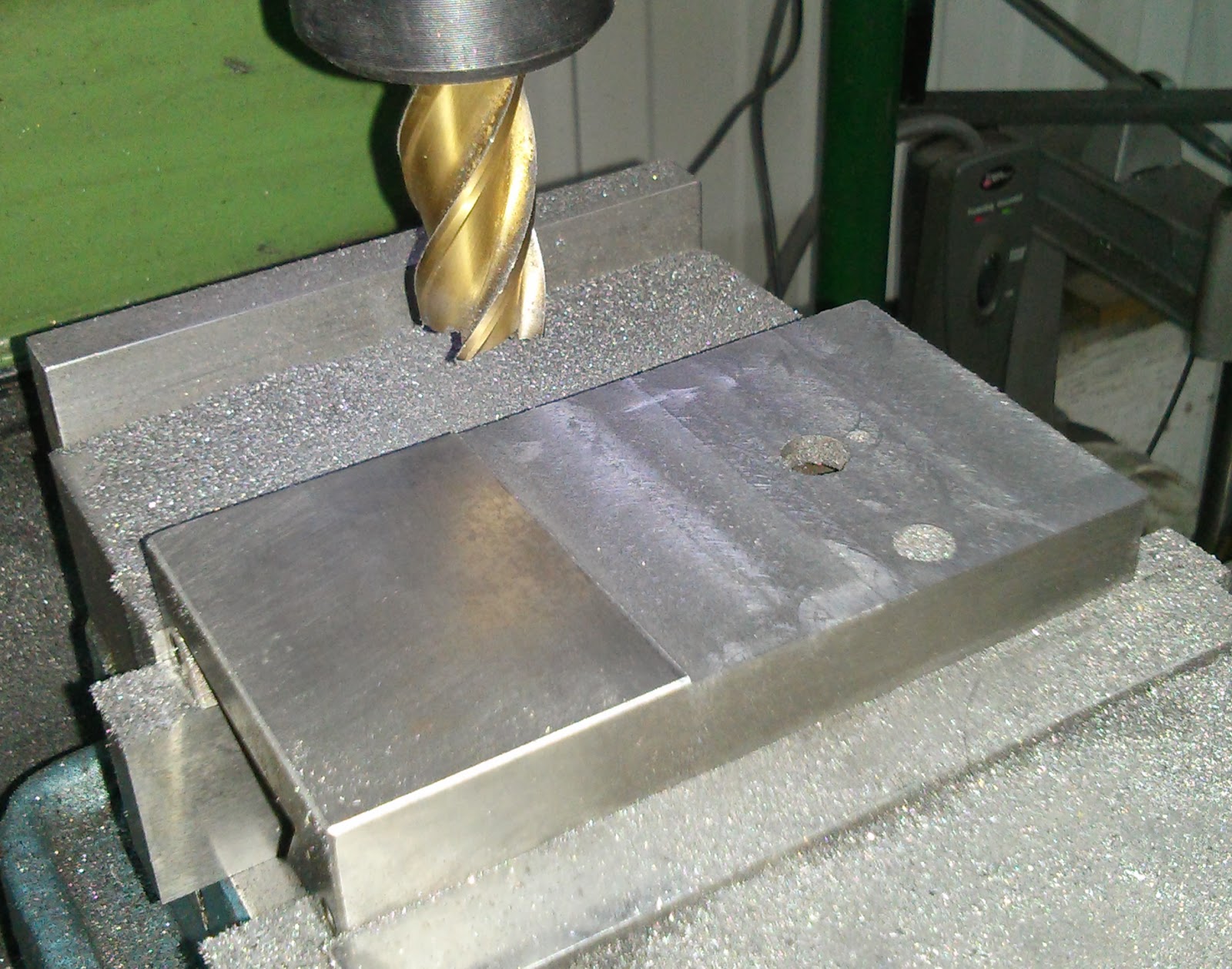

Mill off the raised portion, and then continue to make a recess, perhaps

.05". Too shallow and the tool holders may bottom out, too deep and the

compound slide starts looking thin. The cut will need to continue back

towards the handle a bit to accommodate the tool holder rotating. The

metal is cast iron and cuts easily. After finishing the milling, drill

out the shaft hole to 1/2" and tap 9/6"-18tpi.

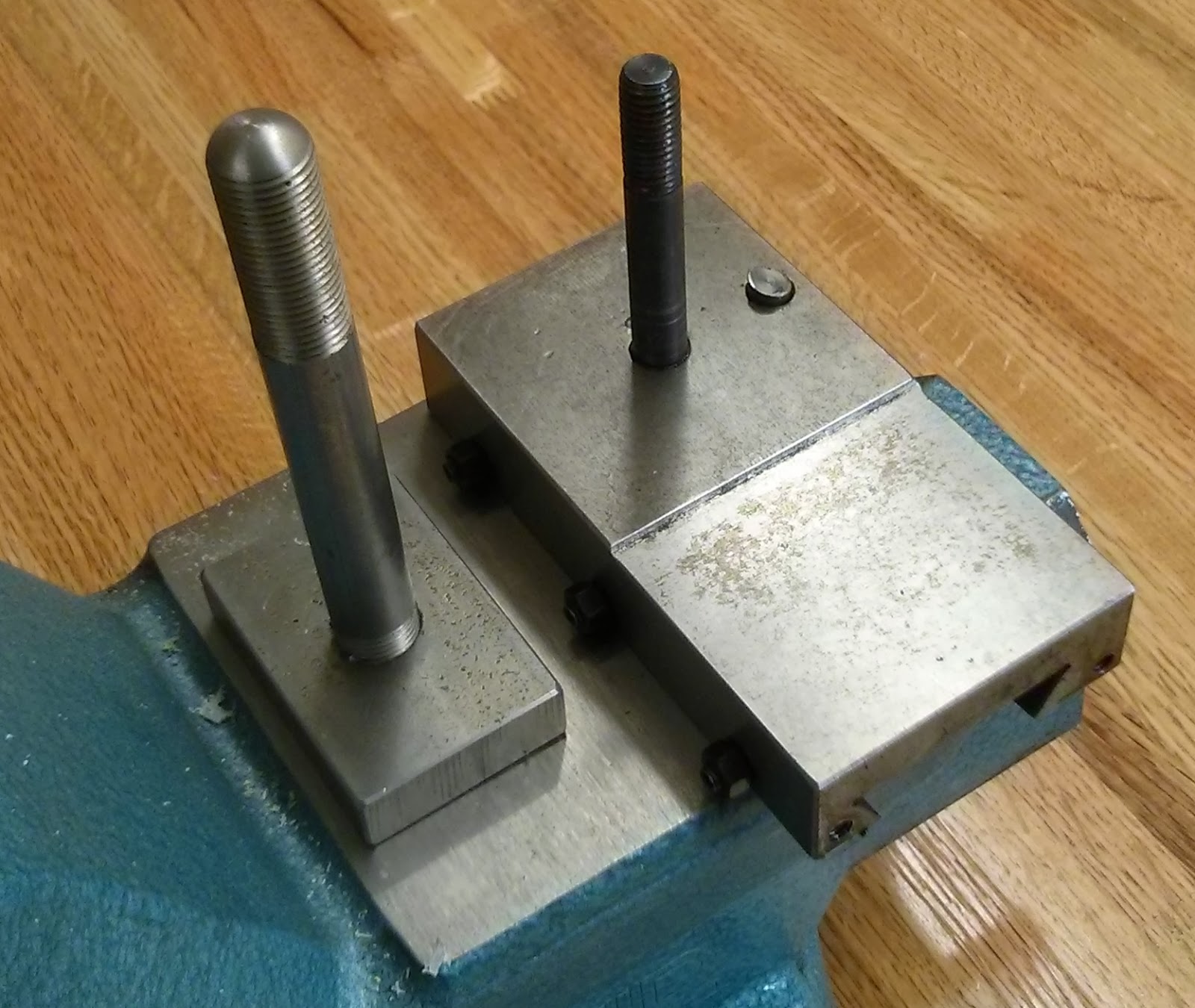

After milling, the tapped portion is thin and may only have three full

threads. To add turns and spread the load, we add a nut in the recess on

the backside of the compound slide. A 1/2" nut has an outer diameter

that fits well. Simply drill it out, and tap it. Mill one side so it's

flush with the bottom of the recess. Tighten it with a socket and mill

the nut-shaft flush with the back of the compound slide.

The shaft-nut must be flush to the bottom of the slide to clear the

brass compound lead screw nut. A little filing of the brass nut may

improve the compound slide action. This SB1001 came from the factory

with some interference.

The compound is ready to be reassembled.

The completed and mounted quick change tool holder is a nice addition to

this lathe. 3/8" tools work well, with some adjustment travel left in

the tool holders. I've not tried 1/2" tools yet, but they will be close

to bottoming out the holders. Consider this when milling your compound

slide, you may want to go a little deeper.