Epix's SV5C10

is a great camera for those wanting to develop solid computer vision

systems. I've used them on several systems with great success, on both

Windows and Linux machines, and appreciate the tolerance of their

software and hardware to changes in the Linux kernel and the well

documented API. Their frame grabber cards use Altera FPGAs, which

creates good feelings, having used both Xilinx and Altera products and

greatly preferring Altera's much nicer development environment. The few

times that I've had minor problems, someone at Epix has always been fast

to provide a solution.

Before using the Epix cameras, I would capture stills using standard

point-n-shoot or DSLR cameras, tethered to a computer and an API

provided by the camera maker, generally Canon. This worked but the Canon

API is unsupported, which also means poorly documented, and, at least

at that time, not available for Linux. Using the consumer cameras for

scientific work is a bit worrisome as well because it's never completely

clear what the camera may be doing to the image, even in raw mode.

These problems do not exist with the Epix cameras, and while slightly

more expensive than the consumer cameras, the cost is very quickly

recouped in reduced programming time and maintenance. Supporting the

consumer cameras through the years as models came and went was a big

time sink.

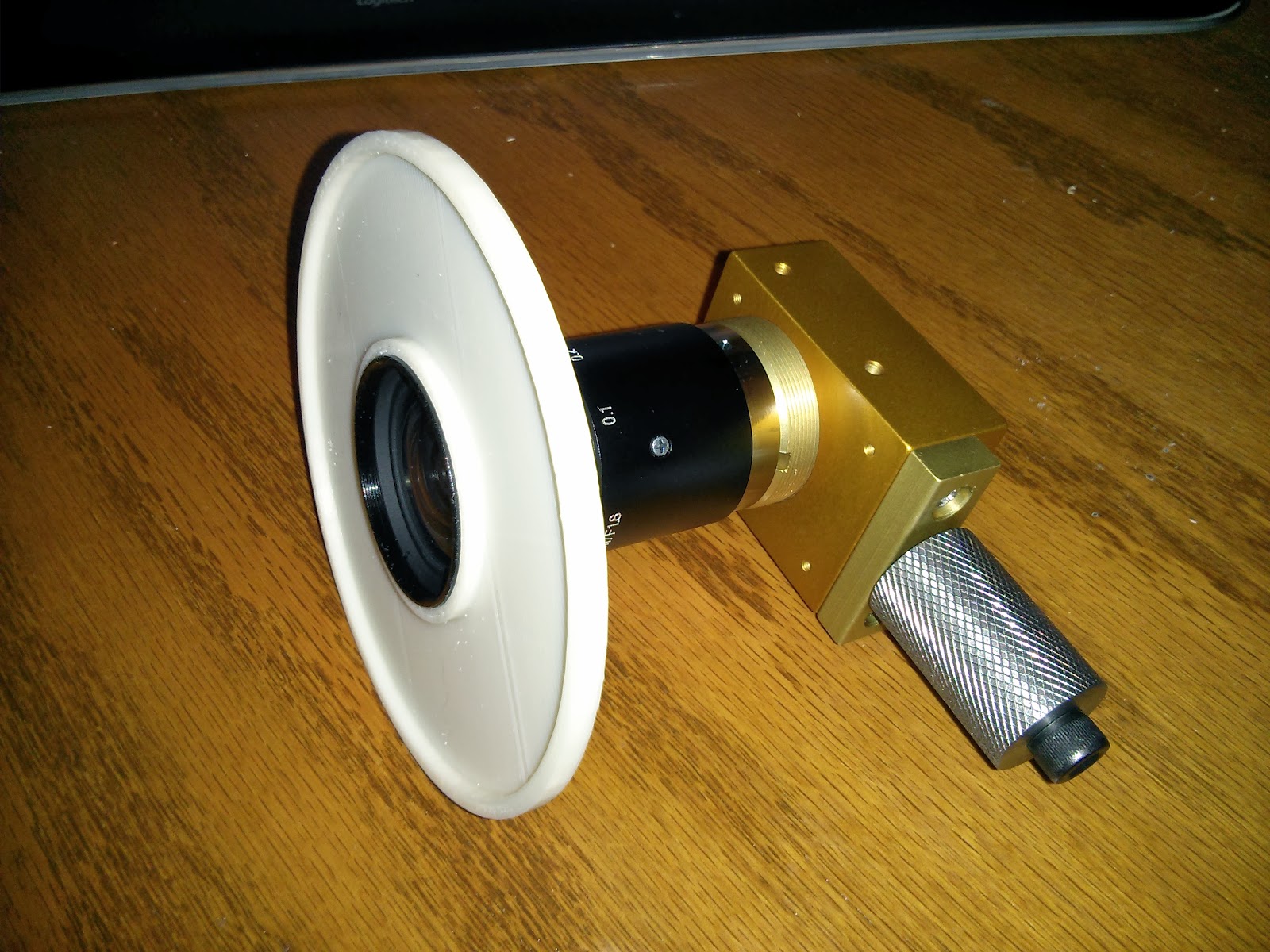

In a recent project, a camera was positioned co-linearly between the

subject and the lights, resulting in some backlighting glare. To block

the glaring part of the light, a small baffle was made. No significant

change in exposure time is needed as little light is actually being

blocked. The rough diameter was found by prototyping with paper models

attached with tape.

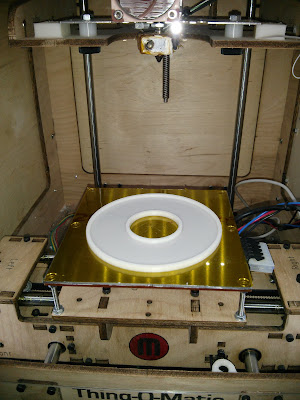

The baffle was printed on the Thing-O-Matic, and added to the end of the

lens with an interference fit. The main disk of the baffle is thin with

thickened inner and outer rings for support. The inner diameter was

bored on a lathe to true it and achieve the correct interference fit.

Without boring, to obtain such tight tolerances, quite a bit of

trial-and-error would be required, due to shrinkage and machine

precision. And while the entire baffle could have been made on the

lathe, the cost would have been much higher due to wasted material, not

to mention being a large for my little lathe.

In addition to the baffle, a small standoff was also made from 1 1/2"

steel rod stock, trued, knurled, and 1/4"-20 clearance hole drilled.

Because stock of the appropriate size was available, and both ends

needed to be very parallel, the lathe was used. The knurling is just for

appearance.

Subtractive machining (lathe, mill, etc.) and additive machining (3d

printing) work well together, and provide alternatives for minimizing

cost and machining time, during prototyping. And in this case with tools

available to many people, not just industry.