The four jaw chuck for the SouthBend SB1001 lathe is sold separately as

the SB1468. However, the camlock adapter still requires machining before

it can attach to the chuck. While performing this machining on the

lathe where adapter plate will be used, matches the two, minimizing run

out, the work can be intimidating. However, the steps consist of routine

operations, and if done slow and carefully great results can be

obtained.

Before machining the adapter plate, the camlock studs must be installed

into the adapter plate. Adjust their height using the line in the stud

as a reference. The studs are secured with cap head screws inserted

beside the camlock studs.

Always clean the mating surfaces of the adapter plate and spindle nose

before fitting. Test fit the adapter plate on the lathe, taking care to

even tighten the camlocks, and securely. The camlocks have marks on

them, and should stop turning near the 6-o'clock point. Adjust the

camlock studs until satisfied with how the camlocks appear.

The spindle nose has an alignment mark to help ensure a chuck is always

mounted in the same position. Make a permanent mark on the new adapter

plate matching with the spindle nose alignment mark, perhaps using a

punch or engraver.

Before continuing, check if there is any gap between the spindle nose

face and the adapter plate. If you can slip a feeler gauge, or piece of

paper between the two, you could have a problem later achieving

repeatable run out. If the gap is substantial, such as in the photo, you

may have a incorrectly machined adapter plate and may want to replace

it.

Now cover the ways of your lathe, and consider running a vacuum to

confine the dust, and wearing a dust mask. The adapter plate is cast

iron and forms a powder when machined, is likely abrasive, and not good

for machine or man.

The actual machining requires only simple operations. First, clean the

surfaces casting by facing the adapter plate lightly. There is hopefully

an inner hub and face that as well. Now, turn the center hub to a

diameter matching your chuck. Take light cuts and go slowly. This needs

to be done so the fit is tight, but not interfering, as perfect as you

can get. Take your time, and sneak up on the diameter slowly. If you go

too far, it's possible to turn the outside diameter to form a new hub,

but it's a lot more work.

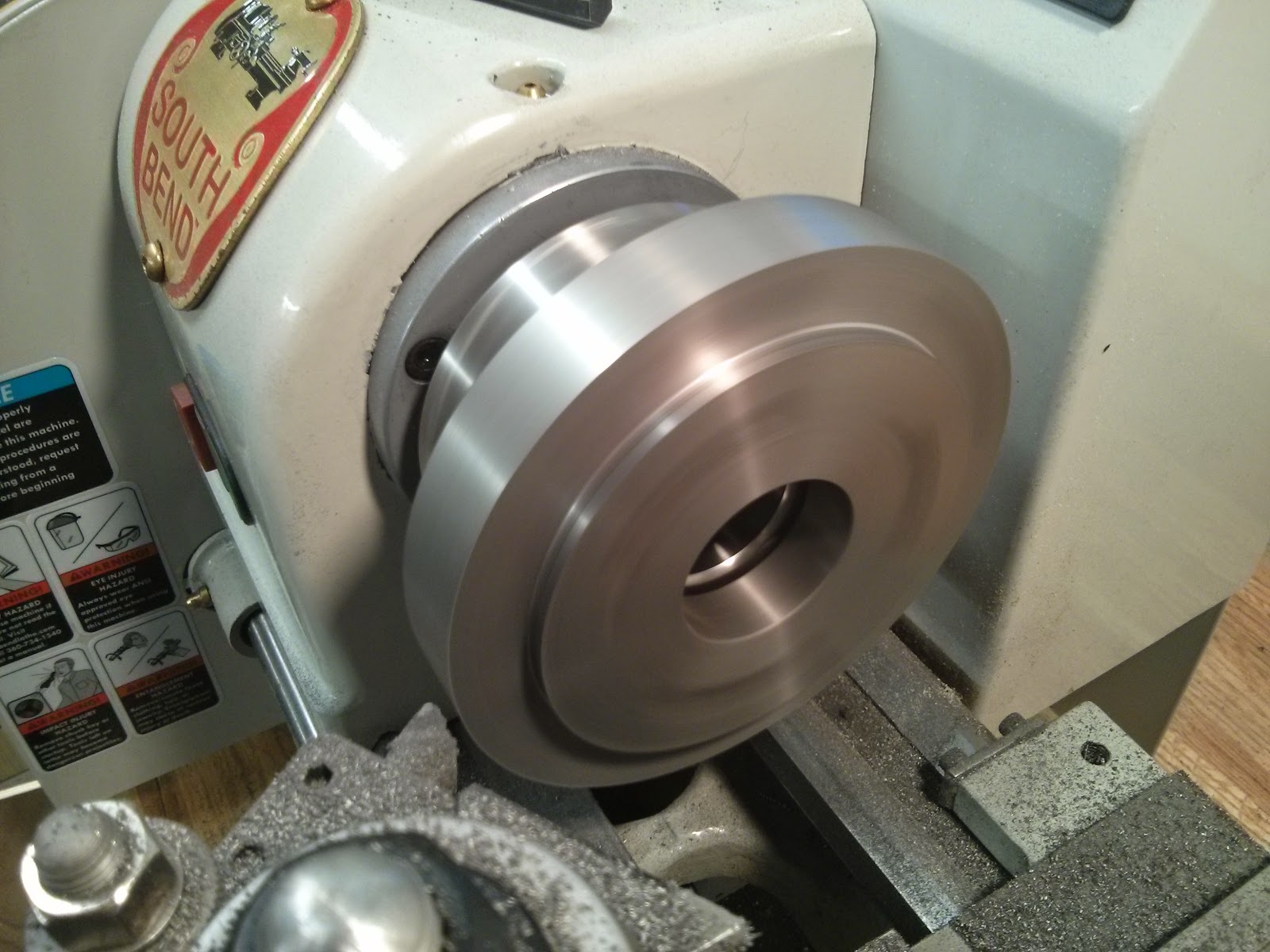

Once the chuck fits the adapter plate, you may want to do a final light

facing pass. Check run on the mounting surface of the adapter plate

using a dial or test indicator. A runout of less than 0.001" is quite

achievable. Now, unmount and remount the adapter plate and recheck the

run out. If run out has increased, recheck the camlocks. Try to follow a

consistent pattern of tightening the camlock to help ensure the adapter

plate is being pulled straight. Make sure the mating surfaces are

clean. Mark positions of run out with a marker and remount the adapter

plate. Is the high spot is consistent, then there's a chance the initial

machining was done with the adapter plate high in a spot. Take a light

facing pass and repeat the run out consistency test. These steps may

need to be repeated a few times. It may be a little frustrating but

being particular at this point will allow you to reduce run out every

time the chuck is used. (The picture shown here is of a larger adapter

plate, but the idea is the same.)

Having achieved minimal repeatable run out, you may want to turn the

major diameter of the adapter plate to true it for balance, but mainly

for appearance. Break the edges with a file, and polish with Scotch

Brite covered in WD40. The surface should look nice after a wipe down.

The chuck attaches to the adapter plate with three cap head screws. Tighten them down evening and snuggly.

Take pride in your work, and enjoy your four jaw chuck.

Epilogue: I wrote these instructions following not finding any available

when I did this work. Also, I wanted to report on a problem others

might experience. The adapter plate I received was not machined right

and did not sit on the spindle nose properly. The adapter plate to

pivoted about a high spot on the mating surface with the spindle nose

and four sheets of paper could easily be slipped into the crack. If the

problem was consistent it may be tolerable, but with each mounting,

despite carefully trying to follow the same torquing pattern, the high

spot would move. With the adapter plate mounted in the three jaw chuck

under power, lightly sanding the high spot using 600 grit sand paper and

WD40, closed up the gap, improving the run out consistency, but the run

out was still greater than expected with a camlock. Grizzly sent a new

adapter plate, but the only one available was a larger model, without a

hub, requiring additional machining. Regardless, the results were much

improved. A thank you to Grizzly for replacing the adapter plate.