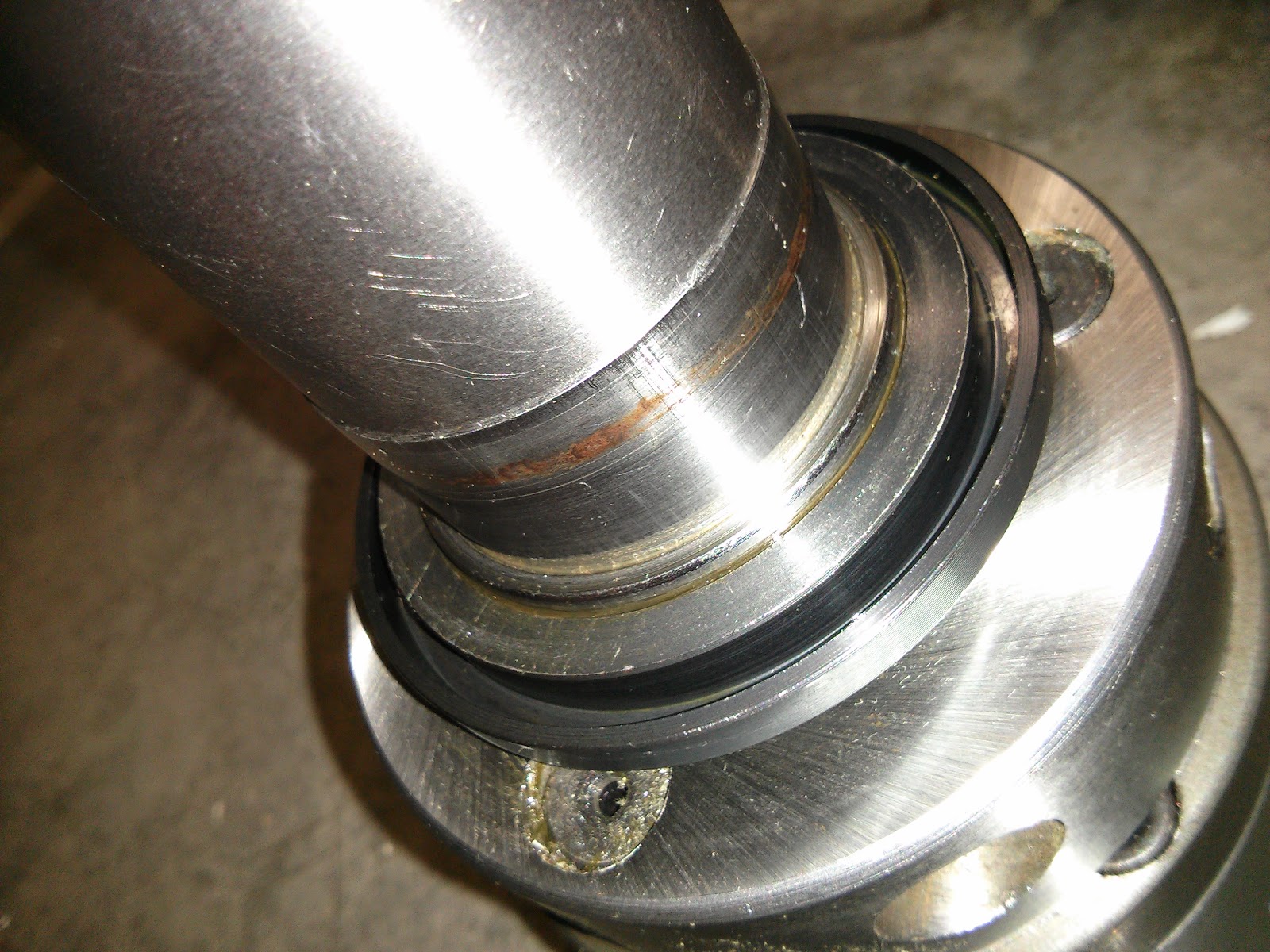

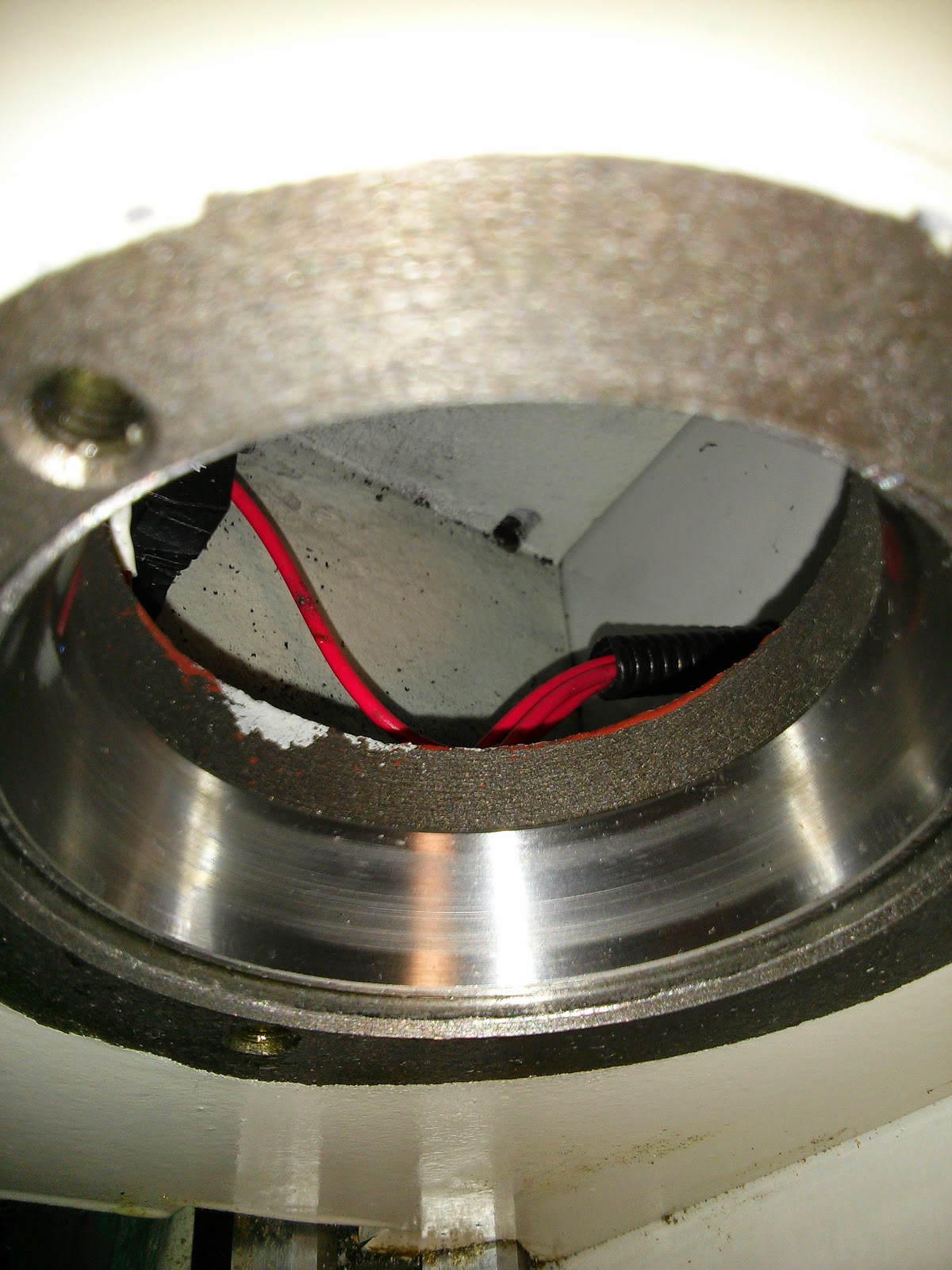

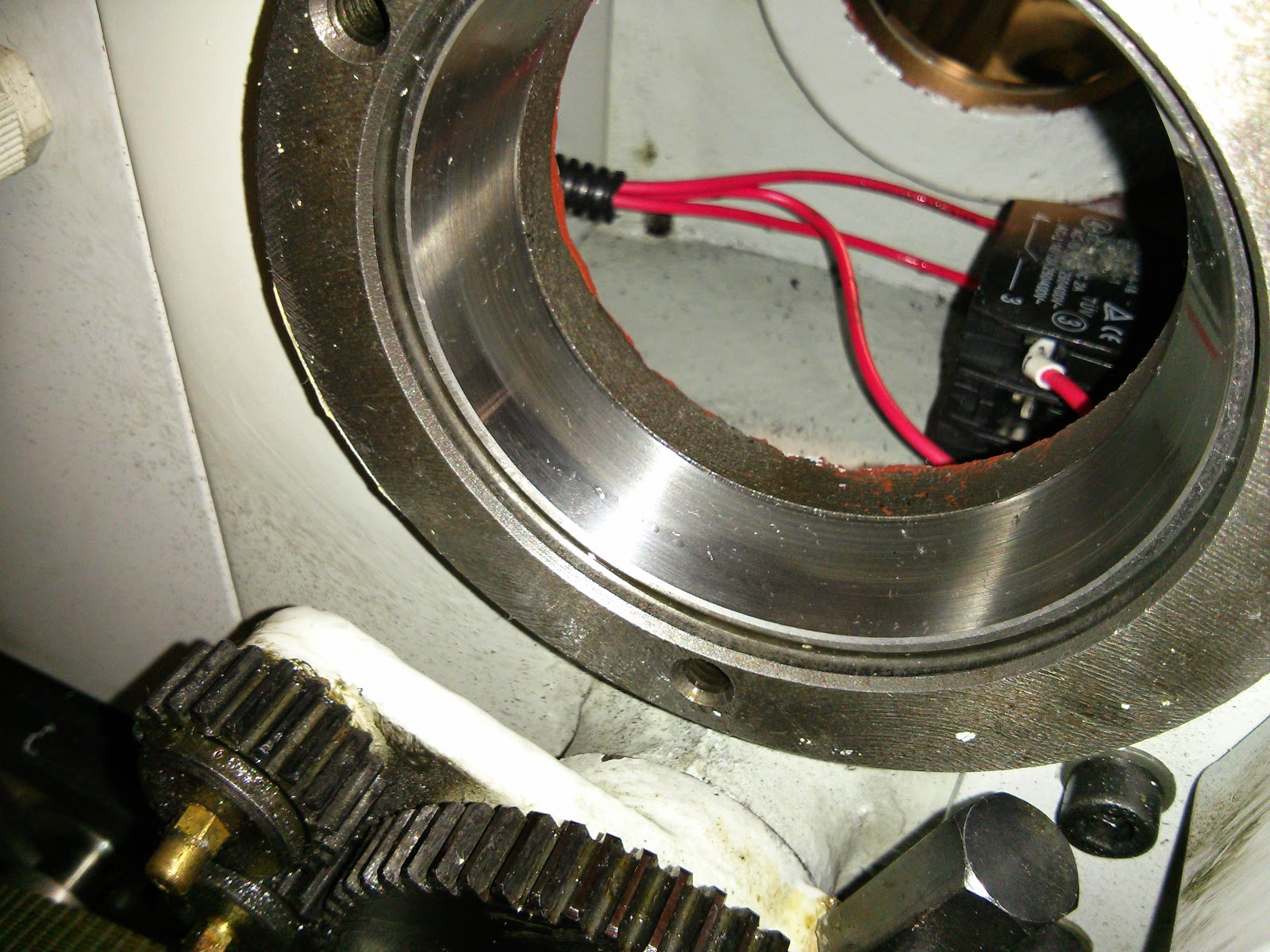

Removing the spindle is straight forward. Simply remove the spindle nut and slide the pulley, gear, and associated spacers off. Gently tap the spindle free, slide the and spindle out. The races are pressed into the headstock, so replacement requires a puller. There were some copper color wear marks, but nothing felt rough.

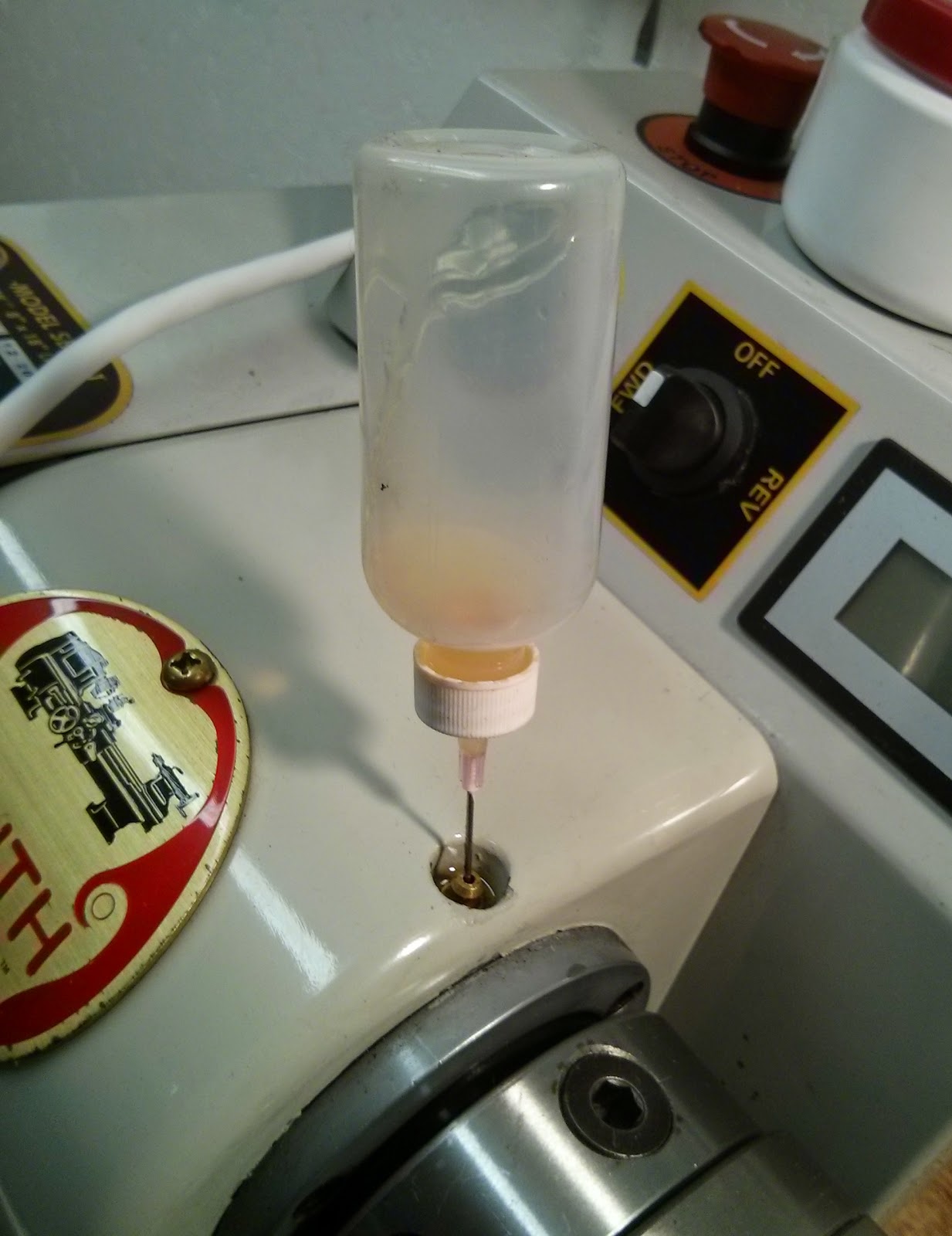

While the spindle is out, take the time to ensure the oil can flow to the bearings. To help with this, consider modifying the two brass grease fittings on the headstock to remove the plunger. If the fitting cannot be removed, the inlet can be drilled out, freeing the plunger. Once the plunger is removed, using a needle oiler is much easier the least messy way. Amazon has empty needle oilers that can be filled with your choice of oil. Blast some WD40 into the grease fitting to clear out the path through the headstock.

Grizzly offered to replace the spindle bearings and entire spindle if I felt the wear necessitated it. That's an impressive offer, but I didn't feel the the wear was bad enough to justify a replacement. If I do replace the bearings, I'd rather use a bearing of a known manufacturer anyway.

From the SB1001 manual, page 49, well past the spindle break-in instructions. Oh well.

Notice: Use only an ISO 32 equivalent oil to lubricate the spindle bearings. Using a heavier lubricant such as grease will cause the bearing to run hot and cause excessive machine wear.

A forum post containing information about this problem and lots of other great information.